Our services

Our Services

Intertek Q&O Services

We are pleased to provide high-quality services at competitive prices, including some free services such as surface unit installation and calibration, along with the manufacturing of selected spare parts. Our company was previously certified by the Ministry of Oil and has successfully executed multiple contracts with the Syrian Petroleum Company and Hayan Petroleum Company.

We specialize in the rehabilitation and servicing of oil and gas wells using our American-made ADICO workover and drilling rig (150-ton capacity), operated by a highly skilled team of engineers, technicians, and field specialists.

Core Areas of Expertise

Current Operational Services:

- Rehabilitation and restoration of oil and gas wells to safely return them to production.

- Water shut-off services for oil and gas wells to restore optimal well performance.

- Well productivity enhancement through acidizing, fracturing, and stimulation operations.

- Downhole pump services: pulling, inspection, repair, and reinstalling downhole pumps, sucker rods, and production tubing.

- Surface unit (Beam Pump) maintenance, repair, and manufacturing of necessary spare parts at our specialized workshops.

- Installation, calibration, and commissioning of surface units.

- Sucker rod repair with the capability to fix damaged joints.

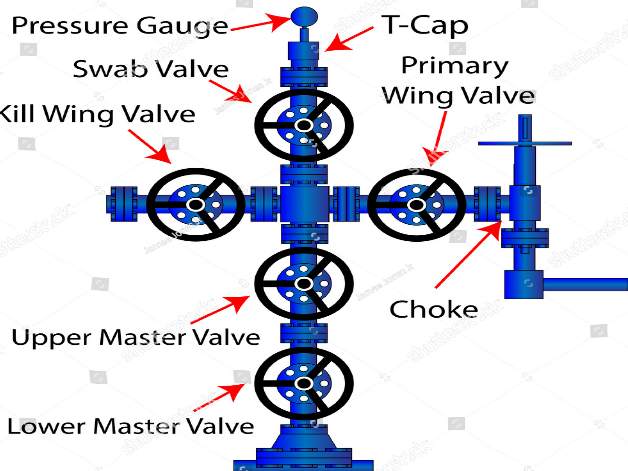

- Maintenance and repair of wellhead Christmas trees (Charismas Tree) and valves of all sizes.

- Manufacturing spare parts for wellheads and valves, including seals, rings, bolts, and flanges.

- Design and fabrication of downhole fishing tools for stuck equipment retrieval.

- Oil and gas pipeline installation from wellhead to processing stations, including cutting, welding, and pressure testing.

- Fabrication and installation of carbon steel tanks for oil, water, and injection purposes with local expertise and high quality.

- Asset integrity testing for tanks and pipelines, including:

1 – Visual weld inspection

2 – X-ray weld testing

3 – Permeability testing (PT)

4 – Magnetic testing (MT)

5 – Pressure and hydro testing

6 – Vacuum box testing for tank base welds

7 – Wet and dry paint inspections

8 – Vibration testing for rotating machinery

9 – Metal thickness measurement and calculation of yearly corrosion rate

- Installation of well collection equipment (Manifolds) at oil and gas station inlets.

Artificial lift pum installation

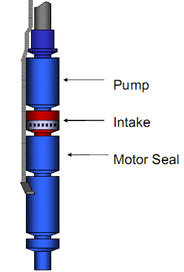

- Installation of submersible electric pumps (ESP) for wells with sufficient production and low-viscosity oil.

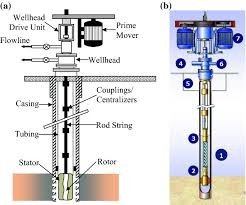

- Installation of Cavity Pumps for wells with high-viscosity oil where surface pumps are insufficient.

- These pumps require a stable and reliable electrical network for proper operation.

Control well in Emergency cases

- Specialized operations to regain control of wells affected by wellhead fires or sabotage.

- The company has extensive expertise in handling these critical situations with highly trained technical crews.

- Successfully performed operations on gas wells where Christmas tree valves were damaged due to explosions and fires.

- Video demonstrations of these operations:

Flame Arrestor Installation

Valve Installation and Well Shutdown

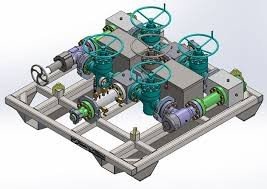

Installion & Operation of mobile test unit(MTU) for oil well test

The company provides oil well testing services without the need for a permanent production facility by deploying a Mobile Test Unit (MTU). This unit is used in the following cases:

- Testing remote wells that are not yet connected to a production facility to determine the well’s output of oil, water, and gas.

- Operating low-pressure oil wells whose production stops when connected to other wells with higher pressure. In such cases, the well is connected to the MTU at low pressure, its oil is collected in a tank, and then pumped to the production facility using a suitable pump.